Cables

Power cables are used in the electricity delivery. High voltage (HV) and extra high voltage (EHV) cables are used in the electricity transmission from generating plants to substations. Medium voltage (MV) cables are used in electricity distribution to connect electrical substations with primary customers or with transformers that serve secondary customers by means of low voltage (LV) cables.

The classic paper insulation has been replaced by crosslinked polyethylene (XLPE) in many sectors due to its low cost and good electrical properties (high resistivity, low dielectric constant and low dielectric loss), its behavior against moisture, low environmental impact and its good mechanical properties. XLPE insulation also has excellent chemical resistance and its properties do not change significantly in a wide range of temperatures.

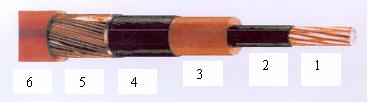

Medium voltage crosslinked polyethylene (MV-XLPE) cables usually consists in a multi-wire stranded conductor of copper or aluminum (1), inner semiconducting layer (2), XLPE insulation (3), outer semiconducting layer (4), copper or aluminum screen (5) and PVC or PE outer jacket (6).

MV-XLPE cables on service reach temperatures of approximately 90ºC and are subjected to stress resulting from permanent electrical and thermal aging. The good properties of XLPE insulation aforementioned are counterbalanced with several issues that are related to their degradation and the lifetime of the cable. The role of space charge has to be taken into account among these issues, as space charge stored in the cable insulation may result in changes in their morphology. There is also an oxidation process associated with generation of polar carbonyl groups. To avoid oxidation, antioxidant agents are added to the cable insulation, which may result in changes in the ability of trapping charge. Antioxidants, crosslinking byproducts and other additives may also produce impurities or defects that may affect the crystal growth and the properties of the amorphous-crystalline interphase, which conditions electrical conduction properties and that may helps to promote the growth of trees and electrical breakdown.

Due to its importance for XLPE insulation electrical features and cable lifetime, space charge is studied by means of Thermally Stimulated Currents (TSDC) and Pulsed Electroacoustic (PEA) techniques. The first one can be useful to detect the dependency of space charge stored in the material on the applied voltage, the poling temperature or the thermal history. It also can lead to qualitative and quantitative studies of the amount of space charge released during the thermally stimulated depolarization for samples with different treatments, additives or manufacture characteristics. The second aforementioned technique can visualize the bulk space charge distributed along the sample thickness. On the other hand, TSDC and Dynamic Electrical Analysis (DEA) techniques make possible to perform relaxational analysis of XLPE. Such analysis provides information about possible polar species in the material, interfacial phenomena, injected charge carriers, etc. All these experimental techniques and analytical methods can help the researchers to elucidate the role played by the additives, crosslinking byproducts, inner and outer semiconducting layers, oxidation, thermal annealing and other phenomena in the cable insulation aging, degradation and breakdown.

Share: